FD1900-3200 Digital Printing Machine

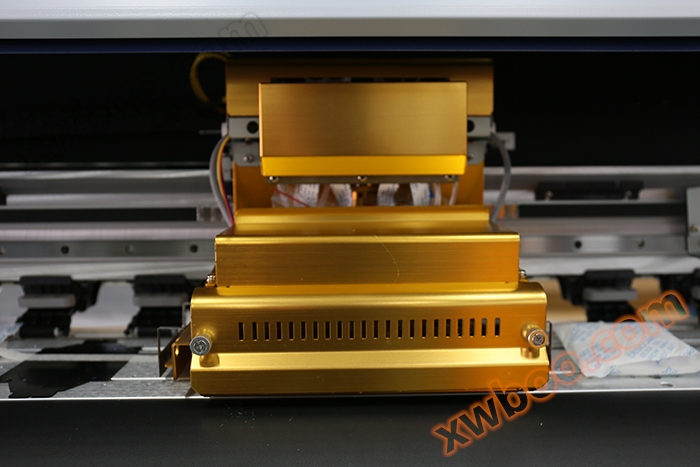

1. Small frame: The independently developed dual head nozzle height can be adjusted freely, flexibly responding to different thicknesses of printing materials, with a luxurious gold color scheme. The anti scratch paper function on both sides of the small frame reduces damage to the nozzle caused by paper warping.

2. Ink cartridges: 4 units of 3L ultra large capacity ink cartridges provide independent continuous ink supply, ensuring long-term continuous operation of the device.

3. Disc filter: effectively removes impurities from ink, ensuring smooth ink supply while protecting the nozzle.

4. Intelligent ink shortage alarm: Intelligent ink shortage reminder reduces the tedious task of frequently checking the remaining ink level, while timely reminding to add ink to ensure the continuity of printing work.

5. Ink stack: equipped with advanced intelligent nozzle cleaning and moisturizing devices, providing safe and convenient nozzle cleaning and maintenance functions, making operation and maintenance more convenient.

6. FD1900 intelligent wind and heat integrated dryer, with two-stage heating, central warm air, and intelligent start stop technology, ensuring more energy-saving while drying.

Technical parameters and specifications

Equipment model |

FD1900-3200 |

|

Nozzle |

nozzle type |

EPSONI3200-A1 |

Number of nozzles |

2 of them |

|

Nozzle properties |

Automatic cleaning, automatic flash spray moisturizing function |

|

PRINT SPEED |

production mode |

3pass \ \ 360X1800dpi 64 square meters/hour square meters/hour |

Equilibrium mode |

4pass \ \ 720X1200dpi 50 square meters/hour square meters/hour |

|

High precision mode |

6pass \ \ 720X1800dpi 32 square meters/hour ㎡/h |

|

ink |

color profile |

C M Y K |

Ink type |

sublimation ink |

|

Ink supply method |

Siphon ink supply |

|

Effective width |

1900mm |

|

Print media |

HEAT TRANSFER PAPER |

|

Media transmission |

Dual power direct collection |

|

Drying method |

External intelligent air and heat integrated dryer |

|

Moisturizing mode |

Fully sealed automatic moisturizing and cleaning |

|

Rip Software |

branchhold |

|

Maintop 6.0, photoprint, ONYX, NeoStampa and other software, standard configuration |

Maintop6.0 |

|

Support image formats |

JPG, TIF, PDF, etc |

computer configuration |

operating system |

Win7 64 bit/Win10 64 bithardware requirements |

|

hard |

tray |

|

500GB or above (recommended to use solid-state drive), 8GB of RAM, graphics card |

: ATI discrete graphics 4GB memory, CPU: Intel quad core i5/i7 processor |

|

Interface |

Gigabit Ethernet portStandard configuration |

|

Tension paper delivery system, intelligent drying system, liquid level alarm system |

work environment |

wet |

linear measure |

35% -65% Temperature: 18-30 degrees |

|

power requirement |

INPUT VOLTAGE210-230VAC 50/60 HZ |

|

16A |

printing system |

1000W |

drying system |

maximum power |

|

∶3600W |

Machine size |

289 |

outline dimension |

400 |

|